History

A pioneer since 1923, Pneumofore has created, developed, patented and manufactured its own innovative products that still set todays’ standards for high efficiency, reliability and longevity.

history timeline

2023

The year 2023 marks Pneumofore’s 100th anniversary, a century of strong and steady commitment to the Rotary Vane technology and the company’s core values: Respect, Integrity, Perfection

The year 2023 marks Pneumofore’s 100th anniversary, a century of strong and steady commitment to the Rotary Vane technology and the company’s core values: Respect, Integrity, Perfection

2022

Rising energy costs make the Pneumofore machines even more appreciated worldwide. We thank all our customers who think about total machine cost over several decades, not a simple look at the pricetag

2020

K2 Series Gas Booster Compressor Systems

with inlet pressure of 6 bar(g) and outlet pressure up to 18 bar(g)

2019

A520 Twin Air Compressor with Variable Speed drive for a wide capacity range, air- or water-cooled

A520 Twin Air Compressor with Variable Speed drive for a wide capacity range, air- or water-cooled

2019

Rolf Hilfiker promoted to Chief Executive Officer

2018

K Series Gas Compressor Systems for gas treatment and gas processing

K Series Gas Compressor Systems for gas treatment and gas processing

2017

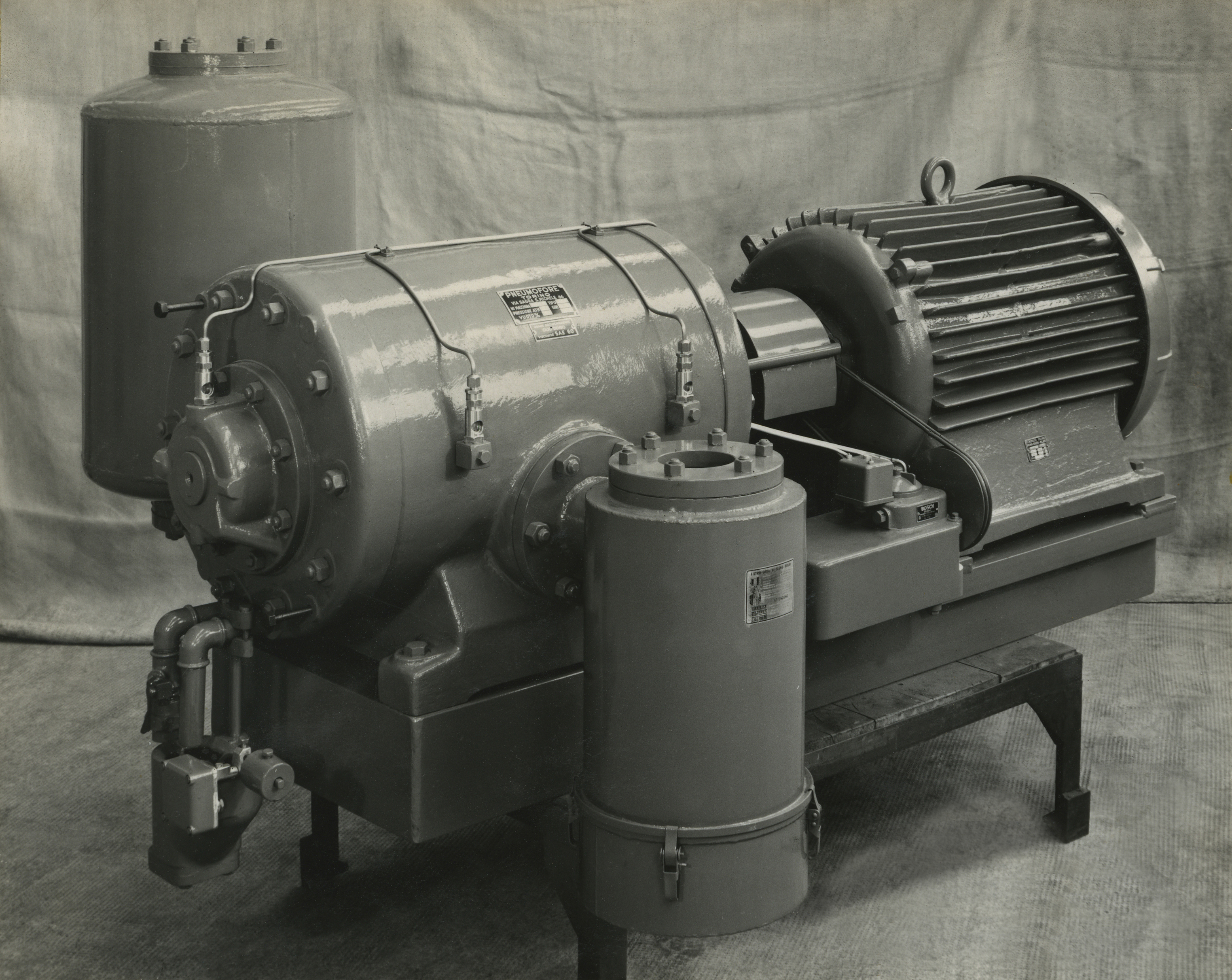

UV24 Vacuum Pump

UV24 Vacuum Pump

Horizontal layout

37 kW for 1.589 m3/h

2016

A150 Horizontal Compressor

New size

2015

Rolf Hilfiker joins Pneumofore as Chief Financial Officer

2015

New Air End casting

New UV and A Series models

2014

UV100 Twin Vacuum Pump

UV100 Twin Vacuum Pump

Two UV50 combined, installed in USA first

2013

UV Ex Vacuum Pump Air-Ends

Vacuum solutions for explosive environment

2012

A VS Variable Speed Series

Variable capacity for high energy savings

2012

A400 Air Compressor

A400 Air Compressor

250 kW – largest air-cooled, single-stage rotary vane model worldwide

2011

A.4 Compressor Series

For low pressure applications

from 2,5 to 4 bar(g)

2010

UV B Double Stage Pump Series

Higher vacuum levels for drying applications

2009

UV BP Vacuum Pump

Dedicated machines for baking with food grade coolant

2008

A HR Series Compressors

Heat Recovery with combined air and/or water cooling

2007

A Series Air Compressors

Motor size according to compressed air pressure value (up to 4, 8 or 10 bar)

2006

Daniel Hilfiker succeeds Robert as President and CEO in June 2006.

2005

UV VS Variable Speed Series

For constant capacity and/or vacuum level

2005

UV4 H Vacuum Pump

For vapor suction

Extraordinary water tolerance

2005

UR26 Compressor

UR26 Compressor

160 kW air cooled, also for tropical climate

2004

UR Explosion-proof Compressors

Tailor made ATEX units for petrochemical industry

2003

UR18 Compressor

110 kW air cooled

2002

UF40 Compressor, 250 kW

Largest air cooled rotary vane, with separate cooling cabin

2000

UV50 Vacuum Pump 2700 m3/h, 75 kW

UV50 Vacuum Pump 2700 m3/h, 75 kW

World’s largest air cooled, single stage rotary vane pump

2000

UR12 Compressor 745 m3/h, 75 kW

New 75 kW compressor (the UP12 was 90 kW) – CE certified and suitable for humid climates

2000

UV8 Vacuum Pump

462 m3/h, 11 kW

Evolution of the UV6, provides more capacity and efficiency

2000

UV16 Vacuum Pump

971 m3/h, 22 kW

Evolution of the UV16, providing higher capacity and efficiency

1999

UR6-9 Compressors 355-550 m3/h, 37-55 kW

New CE-certified 50 HP compressor, suitable for humid climates

1998

T10 Compressor 68 m3/h, 7,5 kW

The T10 replaces the UR1, the smallest of the T series

1998

UF18-26 Compressor 1110-1525 m3/h, 110-160 kW

UF18-26 Compressor 1110-1525 m3/h, 110-160 kW

Cast iron base – Evolution of the previous UF18 model, with simplified structure and optimized pre-separation

1998

Double stage UV30 with roots pump, 3.700 m3/h, 0,05 mbar(a)

Double stage UV30 with roots pump, 3.700 m3/h, 0,05 mbar(a)

1998

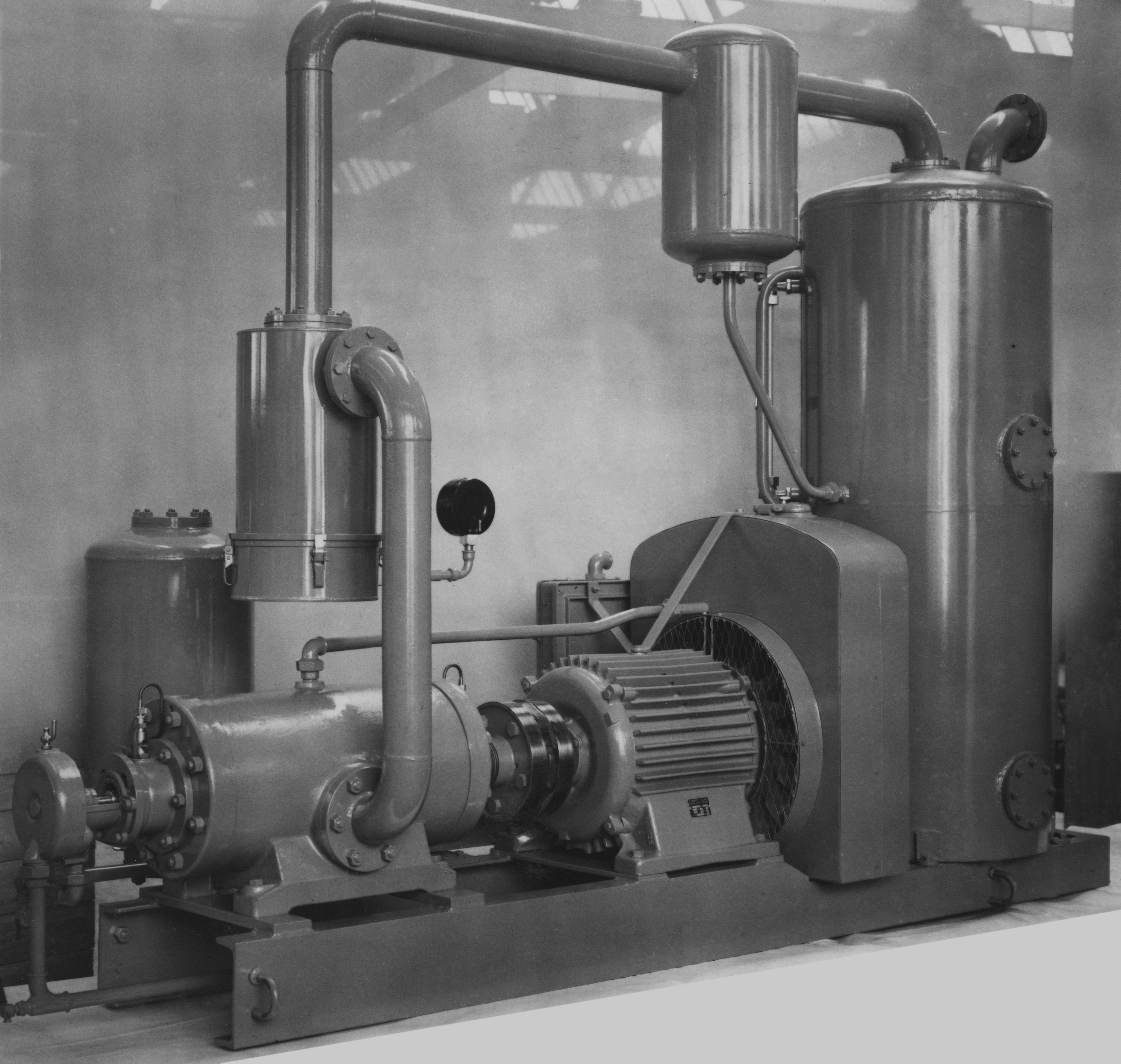

UV30 Vacuum pump 1775 m3/h, 55 kW

UV30 Vacuum pump 1775 m3/h, 55 kW

Maximum-capacity rotary vacuum pump with coolant injection system – with cabin and mono-block – no oil vapor emission. Very successful worldwide. – After 50 years the glorious V100 are finally replaced

1997

T20-30 Compressors 102-168 m3/h, 11-18,5 kW

T20-30 Compressors 102-168 m3/h, 11-18,5 kW

Last small-scale models, completing Pneumofore’s T Series. All models are air-cooled and have 1ppm of oil residual (15-25 HP)

1993

UF18-26 Compressor 1080-1480 m3/h, 110-160 kW

First model with iron base, noisy but provides outstanding performance

1993

UV6-16 Vacuum Pump 428-942 m3/h, 11-30 kW

UV6-16 Vacuum Pump 428-942 m3/h, 11-30 kW

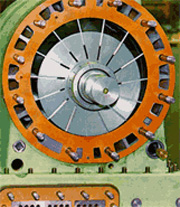

Rotary vane technology applied to vacuum pumps, air-cooled

1992

UR2-3 Compressor 103-166 m3/h, 11-18,5 kW

First rotary compressor with aluminium coolers in cabins

1991

UR1 Compressor 51 m3/h 5,5 kW

Final evolution into the modern aluminium cooler

1991

Heat Recovery is introduced as optional on vacuum pumps and compressors for the recovery of cooling air for heating purposes.

Heat Recovery is introduced as optional on vacuum pumps and compressors for the recovery of cooling air for heating purposes.

1990

Larger air-cooled vacuum pumps are refined in the 1990s to meet the needs of newly-emerging markets

1990

Robert’s children Regula, Martin and Daniel Hilfiker, also an ETH graduate, join the firm at various points in the 1990’s and contribute to modernizing the company’s infrastructure. The T and UR Series air compressors are developed to satisfy a growing international demand for units capable of operating in extreme climates

1986

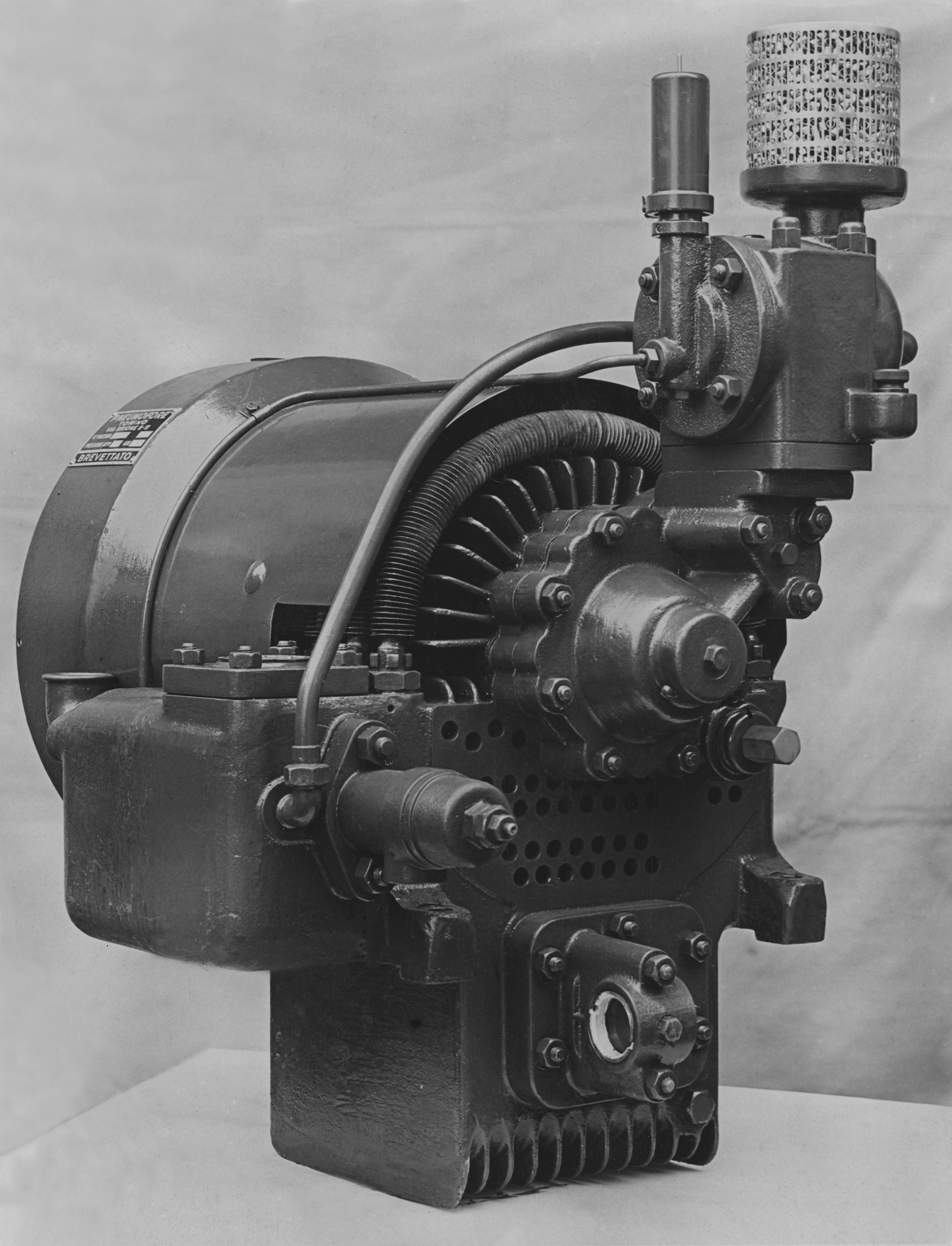

UP9-12 Compressor 530-745 m3/h, 55-90 kW

UP9-12 Compressor 530-745 m3/h, 55-90 kW

Restyling of the U9 axial fan with 2 speeds, for better thermoregulation

1986

UP1 Compressor 51 m3/h, 5,5 kW

Restyling of the U1, with further simplification

1985

UP3-6 Compressor 166-336 m3/h, 18,5-37 kW

Evolution of the U6, with better thermoregulation and electropneumatic control

1981

U9-12 Compressor 530-745 m3/h, 55-90 kW

Large-scale compressors with vertical mixture coolers and radial fans

1981

U1 Compressor 51 m3/h, 5,5 kW

Single shaft for the electrical motor, the rotor and the fan

1980

Focus of R&D concentrates on energy efficiency and environmental integration, key cost factors for any industry after the 1980s

1978

U3-6 Compressor 166-336 m3/h, 18,5-37 kW

First, and for 20 years the only, rotary compressor with vertical axis – Evolution of the UF6 with cabin – Wide coolers with round pipes and turbulators – oil separation with borosilicate cartridges

1970

UF3-6 Compressor 166-336 m3/h, 18,5-37 kW

First compressor with intensive coolant injection system, air-cooled. Produced after intense and in-depth collaboration with ETHZ research institutes, rewarded with international patents

1970

The patented technology of Intensive Oil Injection, developed in collaboration with researchers at the ETHZ, results in high-efficiency air compressors. From 1970s on, Pneumofore experiences strong growth and the development of new markets abroad

The patented technology of Intensive Oil Injection, developed in collaboration with researchers at the ETHZ, results in high-efficiency air compressors. From 1970s on, Pneumofore experiences strong growth and the development of new markets abroad

1965

FA3 Compressor 5 HP

Air-cooled – Vertical layout – Copy of 1937’s FA15 – 5 HP motor

1964

F360 Compressor

F360 Compressor

3720 m3/h, 500 HP

Last compressor designed by Pneumofore’s founder Giacomo Hilfiker

1964

Alfred Hilfiker and Robert Hilfiker, a graduate of the Swiss Federal Institute of Technology in Zurich (ETHZ), assume leadership of Pneumofore in 1964. Work begins on numerous innovations: air-cooled compressors and vacuum pumps, vertical machine layout, tangential vanes, turbobooster for automobiles, and more

1959

F28 Compressor 280 m3/h, 41 HP

Prototype with F28 cylinder, 4-pole motor and iron base

1957

MSV2-9 Vacuum Pump + Blower 25-114 m3/h, 1-4 HP

MSV2-9 Vacuum Pump + Blower 25-114 m3/h, 1-4 HP

New development of air-cooled mono-block vacuum blower pumps, mainly used for typography

1957

F200 Compressor 2080 m3/h, 270 HP

For many years the maximum unit power (300 HP) for a single-stage rotary compressor

1954

FB10 Compressor 95 m3/h, 17 HP

Air-cooled

1952

F120 Compressor 1237 m3/h, 170 HP

First Pneumofore compressor with sliding rings – Hundreds of these are still functionning all over Italy and Europe. The base was initially made in iron. In 1968 a cast-iron base was built for better air/oil separation and less noise

1949

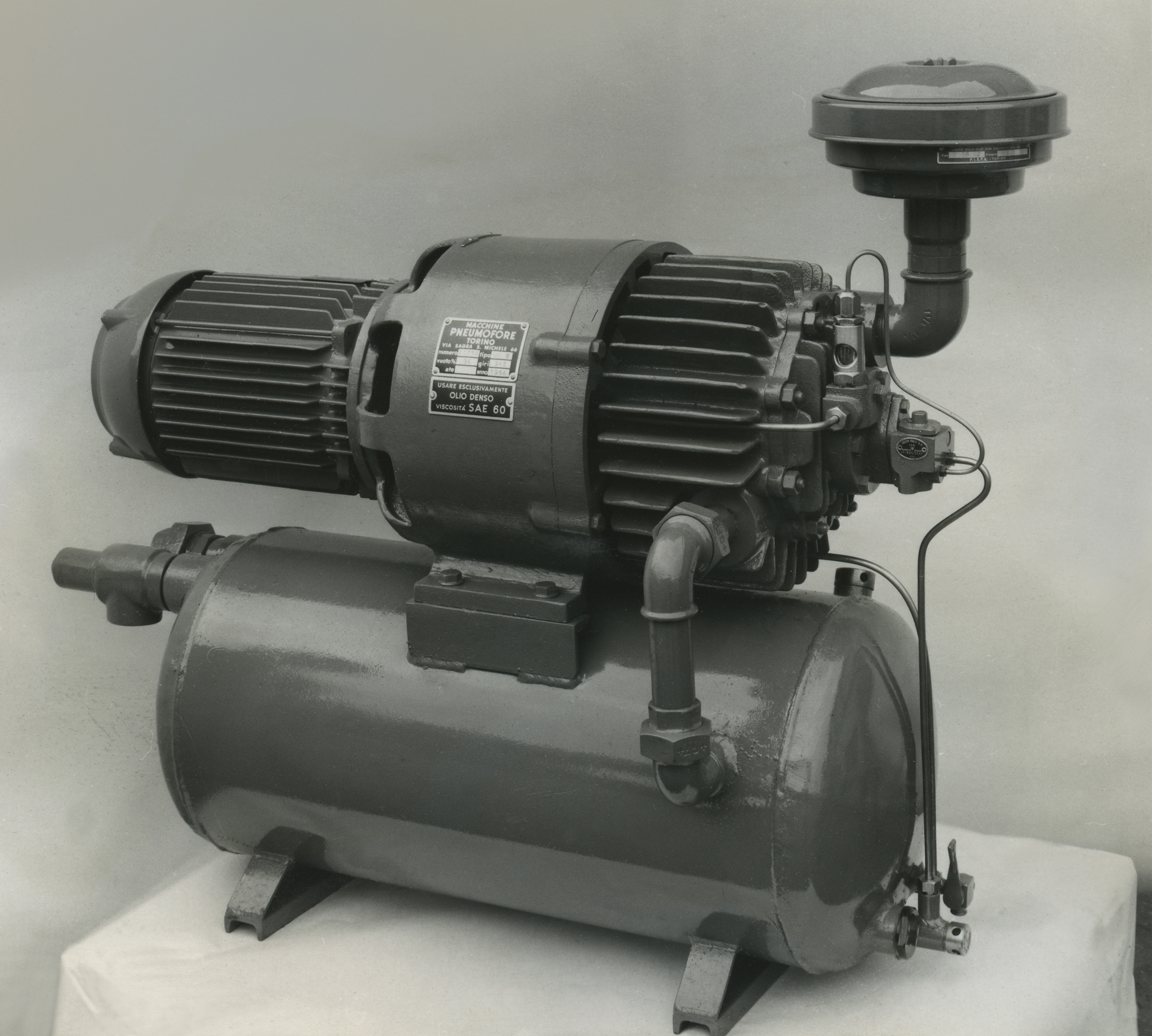

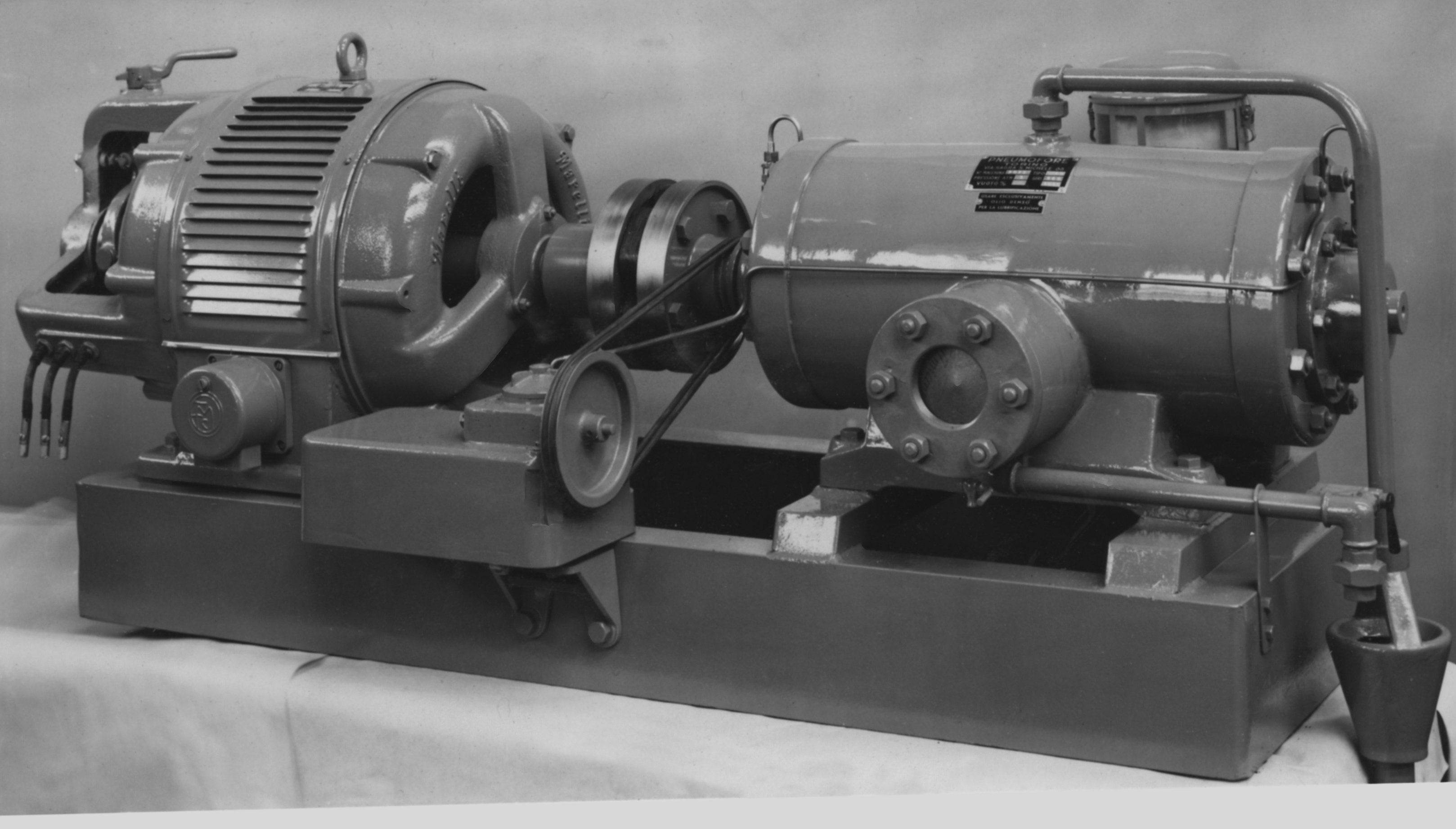

V100 Vacuum Pump 1220 m3/h, 35 HP

V100 Vacuum Pump 1220 m3/h, 35 HP

Development of a pump, which had been produced for 48 years and immediately obtained an unprecedented final single-stage vacuum: 14 mbar of residual pressure (98% vacuum)

1947

Z90-200 Oil burner

Heavy oil burner with turbo-fan and pulverizer cone, used in big buildings, cinemas and industrial plants

1943

FA7-19 Compressor

Air-cooled compressors in cast iron mono-block with cooling fins

1939

F28-40 Compressor 280-415 m3/h, 42-60 HP

Ten years later two new models of water-cooled industrial compressors with cast iron base are produced. Many of these are still functioning

1937

FA15 Compressor 2,5 HP

FA15 Compressor 2,5 HP

Vertical layout – First air-cooled rotary compressor with vertical layout, 2,5 HP

1935

E10-60 Oil burner

New series of mono-block heavy oil burners used for domestic heating

1935

F80 Compressor 765 m3/h, 110 HP

First model of the F Series, which significantly contributed to the Pneumofore history and supplied the heavy industry for decades

1932

FC9 Compressor

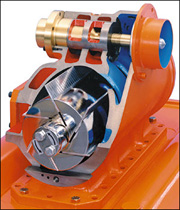

First air-cooled single-stage rotary compressor with oil injection system – 30 HP motor

1932

FC17 Compressor

Air-cooled

1932

SP0 Blower

New series of blowers for oil burners

1932

SP1 Blower

For oil burners. Major model of the SP0-1-2-3-4-5

1929

FM9-18 Compressor 93/181 m3/h, 15/30 HP

First water-cooled mono-block, single-stage compressor

1927

A12 Compressor – 7 bar, 10 HP. The very first single-stage compressor with coolant injection system – 25 HP – A unique, revolutionary solution created by Pneumofore’s technicians, at a time when single-stage piston compressors were dominating the market

A12 Compressor – 7 bar, 10 HP. The very first single-stage compressor with coolant injection system – 25 HP – A unique, revolutionary solution created by Pneumofore’s technicians, at a time when single-stage piston compressors were dominating the market

1927

V6/6 Vacuum pump

Double-stage vacuum pump, 980 rpm, 1,5 mm Hg residual pressure

1927

V45 Vacuum pump 524 m3/h, 15 HP

V45 Vacuum pump 524 m3/h, 15 HP

Double-stage – First medium-size vacuum pump, used for chemical industry and food manufacturing

1927

C45 Compressor 406-460 m3/h, 20-43 HP

C45 Compressor 406-460 m3/h, 20-43 HP

Low pressure (2-3 bar) – Used in glass industry for bottle production

1927

SA4 Blower

Air-cooled S4 model replaces water-cooled C4 model, Pneumofore starts avoiding use of industrial water whenever possible

1927

F18 Compressor 180 m3/h, 30 HP

30 HP motor – Second, modified prototype of major single-stage rotary compressor

1926

S4-20 Blower

Used with heavy oil burners

1926

V4 Vacuum pump

Aluminium vanes – First of many V-MV-UV Series vacuum pumps

1926

V14-20 Vacuum pump 174-228 m3/h, 7,5 HP

Aluminium vanes – Pneumofore’s innovative use of aluminium vanes remained unique for over 40 years

1925

C9 Compressor 91-102 m3/h, 4,5-11,5 HP

Low pressure – Series of compressors (2-3 bar), blowers and C4-9-20-35 vacuum pumps

1923

Jakob HILFIKER (1895-1964) founded Pneumofore in 1923

Jakob HILFIKER (1895-1964) founded Pneumofore in 1923