View Pdf » EN

Powering the World’s Largest Container Glass Factory with Advanced Vacuum Systems

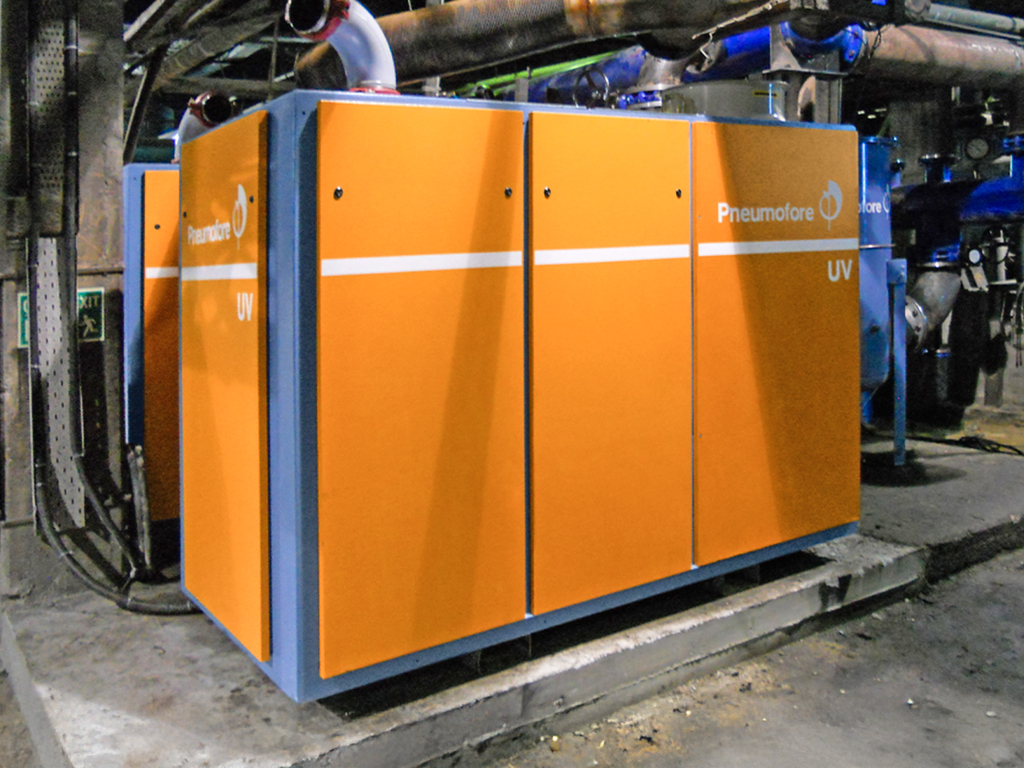

For over 20 years, Pneumofore has supported Șișecam with durable vacuum solutions, most notably at its Eskișehir plant – now the world’s largest container glass factory with five furnaces, 24 production lines and 760.000 gross tons annual capacity. The site hosts one of the largest installations of Pneumofore hollow-glass pumps in Turkey, some operating since 2002 without overhaul. With innovations like UV50 rotary vane pumps, variable speed drives and advanced filtration, Pneumofore ensures efficiency, reliability and cleaner operation. Across Șișecam’s key plants, 27 units of UV50 pumps sustain production, confirming Pneumofore as Șișecam’s trusted partner in long-term, energy-conscious pneumatic machinery supply for glass manufacturing.

Pneumofore has been a trusted partner of Șișecam for more than two decades, supplying vacuum technology across multiple countries. In 2024, Șișecam’s Eskișehir facility resumed operations of one of its glass furnaces after a major cold repair. Today, the site has reached a remarkable milestone: with five furnaces and 24 production lines, it stands as the world’s largest container glass manufacturing plant, boasting an annual capacity of approximately 760.000 gross tons.

This scale is the result of deliberate investments and long-term strategic choices. It is no coincidence that the largest installation of Pneumofore vacuum pumps for hollow glass is found precisely here. Some Pneumofore air-cooled rotary vane pumps, first installed at Șișecam as early as 2002, continue to operate smoothly – without a single overhaul in over two decades. Designed for continuous, 24/7 operation, Pneumofore’s UV Series rotary vane pumps require only minimal yearly maintenance, such as coolant and filter replacements, to maintain efficiency and reliability over decades.

Where traditional swabbing methods involve graphite-based lubricants, Pneumofore systems integrate demister vacuum filters with dual-stage filtration and discharge mechanisms, ensuring stable performance and cleaner operation. Over time, the technology has continued to evolve: the UV30 model was succeeded by the UV50, offering 2.750 m³/h capacity with a 75 kW motor. Șișecam has progressively replaced liquid ring systems with Pneumofore rotary vane pumps – most often selecting the largest available models. Recent deliveries, including those in 2024, are equipped with variable speed drives for enhanced energy efficiency and adaptability.

Pneumofore also offers the Hot Climate HC version of air-cooled UV50 vacuum pumps, which operate up to 50 °C ambient temperature. Over the years, the advantages of having air- instead of water-cooling summed up and consolidated the preference for the rotary vane solution of Pneumofore. In fact, Turkey experiences severe summer water scarcity due to climate change and declining rainfall, combined with increased demand and excessive groundwater extraction contributing to the problem. Many areas, including the tourist coast, are implementing emergency water restrictions and searching for groundwater sources to cope with the mounting water crisis, which risks becoming worse.

Currently, the three major Șișecam plants in Turkey – Yenișehir, Eskișehir and Mersin – operate 27 units of UV50 pumps. While alternative suppliers have been tested over the years, many lower-cost solutions proved unsustainable, often showing significant performance deterioration after only a few years of heavy-duty operation. By contrast, Pneumofore’s machines have demonstrated resilience and consistency, securing their role as a preferred choice for long-term investment.

As the Turkish glass industry continues its expansion, now also in Europe, Pneumofore remains committed to delivering robust, energy-conscious vacuum solutions. This partnership highlights not only the value of advanced engineering but also the wisdom of selecting equipment designed to endure.