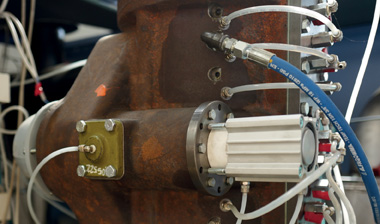

The new casting for the housing of the air ends that fits the new A150 air compressor and the UV24 vacuum pump is well defined. Presently we analyse precisely how to optimize the machine efficiency at different pressure levels. No lubrication pump is found in a traditional Pneumofore rotary vane machine; the oil circuit is kept “active” for cooling and lubrication by using the machine internal pressure differences. The picture shows the newly designed UV24 vacuum pump with vertical layout. The lubrication pipes have singular flow settings to inject the exact amount of coolant, depending on the operational value that can vary from 0.5 mbar(a) to 40 bar(g). Like this, every air-end housing has a different machining procedure, precisely set for a specific application.

In Pneumofore, continuous innovation comes from our people, a strong team of dedicated employees, each one with his own specialization and know-how. The human factor is a huge contribution to the way we do business and a key element in our production processes, which are not strongly automatized. Having so much hand-work involved in our assembly procedure, we must keep a strict quality control and machine testing sequence, to avoid any risk of human mistakes. These accurate checks make sure that our machines are delivered fault-free. As a measure of our production quality, at Pneumofore we traditionally divide the total cost of warranty by the yearly turn over. In 2015, this indicator was reduced to a very low 0,48% value, which means that hardly any customer asked a warranty replacement during the last year. We are extremely glad for this result, which reflects our passion for continuous improvements towards ever-higher quality standards, and strengthens our image as a manufacturer of highly reliable machines for the lowest environmental impact.

As a leading supplier of centralized vacuum and air systems for the can industry, Pneumofore will participate in Euro CanTech 2016, the technical conference and exhibition for the metal packaging industry that will be held in Berlin, Germany, from 4 to 6 April. Eng. Daniel Hilfiker, President and Owner of Pneumofore, will be among the keynote speakers of the event to demonstrate the advantages of centralized vacuum and compressed air supply in can lines worldwide with the presentation ‘No Cans without Vacuum’ on April 5th at 11:00 AM. Alongside the technical conference, Pneumofore will welcome the conference attendees at the concurrent tabletop exhibition. With references such as Rexam, Ball, Can Pack, Crown Cork, United Can and many more, Pneumofore ensures top pneumatic expertise to the global can industry.

Back from Tire Technology Expo, the leading tire moulding exhibition in Hannover. The update on innovations is relevant to speed-up manufacturing processes for optimized productivity. A note regarding vacuum in tire moulding factories: the traditional spikes on new tires are disappearing, replaced by round signs from minivents; the way that tire moulds are evacuated is improving. This alone brings the following advantages: vacuum is used only upon request by means of spring vents, which reduces the power consumption of the vacuum pump, as the suction holes are securely closed, when required. Secondly, stickers on tire fronts, as applied in large storages to identify the tire model, will stick and remain. Before, the rubber spikes were jeopardizing the long-term adherence of the stickers on the tire profiles. Pneumofore could observe the market and technology trends plus follow up interesting projects, besides those with long-term customers like Michelin and Good Year, now also with Continental. See you there again in 2017!

The year just started and we registered a full order book, mostly with the large-size A400 air compressor, both in its low pressure version from 2,5 to 4 bar(g) and in the mid-pressure from 5 to 8 bar(g). The minimal installed nominal power is 250 kW, its hot climate HC version has a 315 kW motor installed. A frequent shipping destination are glassworks in Asia, the compressors are used for the hollow glass moulding process and for the manufacturing of tableware. The customers usually experience the extraordinary efficiency and reliability of Pneumofore machines starting from the vacuum side. After decades of continuous running, the rotary vane vacuum pumps of the UV Series keep on perform as new; this is the undiscussed statement which brings our distant customers to also invest in A Series air compressors.

Not frequent, but not the first time that Pneumofore installs vacuum pumps in Southern Africa. The solution with air-cooled vacuum pumps for glassworks and the trouble-free operation over 10+ years has been experienced in other glass plants in Nigeria, Ethiopia and South Africa. Good references are our first and best sales tool, these distant customers are satisfied, even though there is no local service centre. Training about ordinary maintenance is given to the customer during the commissioning phase, so that he can operate and service independently. In the picture are 3 pumps model UV16.

- 1

- 2