ProPak Asia marked another successful step in strengthening Pneumofore’s footprint in South-East Asia and reaffirming the company’s commitment to durable, energy-efficient vacuum and compressed air systems for the packaging industry.

Held in Bangkok, Thailand, the exhibition attracted thousands of professionals from the processing and packaging industries for food & beverage, FMCG, pharmaceutical, cosmetics and other consumer products. The event offered a comprehensive showcase of the latest advancements and market trends, with a strong focus on sustainability, innovation, and energy efficiency.

Alongside its long-standing local distributor, Star Dynamic, Pneumofore presented its latest Rotary Vane vacuum pumps and air compressors, specifically designed to meet the demanding requirements of the packaging industry.

At the heart of packaging processes – such as vacuum packing, MAP (Modified Atmosphere Packaging), moulding and pneumatic conveying – reliable vacuum and compressed air are essential for production speed, consistent product quality and efficiency.

With rising awareness of energy consumption and system longevity, Pneumofore’s Rotary Vane technology is valued as a smart investment for packaging companies focused on long-term performance and eco-conscious packaging lines. Its vacuum and compressed air systems stand out for their low Life Cycle Cost, long-term durability, and minimal environmental impact, aligning perfectly with the growing demand for sustainable technologies in South-East Asia’s booming food and beverage sector.

Pneumofore successfully returned to China Glass 2025, reaffirming its long-standing commitment to the Chinese glass industry. Exhibiting within the Italian Pavilion, Pneumofore presented its full range of Rotary Vane vacuum pumps and air compressors tailored for hollow glass production.

Pneumofore has built a strong reputation in the region for delivering energy-efficient, air-cooled, and durable vacuum and compressed air solutions. These systems are engineered to lower emissions, reduce operational and energy costs, and ensure the lowest Life Cycle Cost (LCC) available on the market – key benefits for energy-intensive glass production lines.

With the collaboration of its local partner, Christo Consulting, Pneumofore is strongly committed in expanding its presence in China across the glass sector and other industrial fields, enhancing its support and sustainable innovations in one of the world’s most dynamic industrial markets.

Addressing the high energy demands of utilities like compressors and vacuum pumps in canmaking was the focus of Pneumofore’s participation at LATAMCAN 2025, the leading conference for the metal packaging industry in Latin America. Held in São Paulo, Brazil, the event gathered canmakers, suppliers, and key decision-makers from across the region, reaffirming its role as a key meeting point for the global can manufacturing sector.

As a trusted partner in aluminium can production, Pneumofore returned to the event to present its Rotary Vane vacuum and compressed air solutions for 2-piece can lines, with a strong focus on durability, energy efficiency, and CO₂ emissions reduction. Pneumofore systems are designed to meet sustainability goals by significantly lowering operational energy consumption and reducing environmental impact.

A key moment of the conference was the presentation by Pneumofore’s CEO, Mr. Rolf Hilfiker, who emphasized how utilities can be both energy-intensive and maintenance-heavy—two concerns that can keep production managers awake at night. Pneumofore answers with a proven combination of reliability, constant efficiency over decades, and very low maintenance needs. The Rotary Vane technology, which is at the core of Pneumofore vacuum pumps and compressors, has proven to offer the lowest Life Cycle Cost available on the market.

Beyond machinery, Pneumofore offers a Total Responsibility package, covering on-site service, spare parts, fast interventions, transportation, lodging, and more—ensuring peace of mind without even relying on remote control systems.

Pneumofore’s successful participation was enhanced by the valuable support of the local distributor, 7-Ogun, who ensured a smooth presence throughout the event.

With decades of presence and growing references in Latin America and the support of its local partners and service centers, Pneumofore continues to deliver tailored, energy-efficient and worry-free vacuum and compressed air solutions that redefine efficiency in can production.

Compressed air and vacuum are extremely important in 2-piece can production. Having reliable and durable equipment is essential to guarantee constant efficiency and high saving in the long-run.

Since 2019, Envases Universales relies on Pneumofore for the supply of pneumatic energy in some of its plants in Mexico.

Envases Universales is a leading worldwide supplier of quality packaging products for beverage, food and other industrial sectors. The Group is strongly committed to innovative and sustainable solutions in packaging production and to minimize the environmental impact of the full production cycle. Therefore, they choose and cooperate with suppliers that ensure the highest quality standards in terms of efficiency, energy saving and sustainability.

Pneumofore vacuum pumps as well as low and high-pressure compressors were firstly installed in the Pachuca plant, Hidalgo. The benefits of using the Rotary Vane technology of Pneumofore are clear to the customer: enduring efficiency, rare maintenance, seamless operation even in Hot Climate conditions are the resulting considerations of Envases Universales, accompanied by the confidence of having the most advanced levels of excellence, energy saving and sustainable technology available on the market.

Energy efficiency and sustainable glass manufacturing were at the heart of Pneumofore’s presence at Glassman Europe 2025, the international technical conference and exhibition dedicated to the glass industry. Held in Istanbul (Turkey), the event brought together global experts, hollow glass and glass containers manufacturers and suppliers operating in the sector.

As a trusted global partner for glass manufacturing, Pneumofore showcased its energy-efficient vacuum and compressed air solutions. Renowned for their constant performance over time – even in hot climates and remote locations – Pneumofore’s water-saving, air-cooled Rotary Vane systems are recognized for their major operational advantages.

A highlight of the event was the technical conference, where Eng. Daniel Hilfiker, President of Pneumofore, delivered a keynote titled “Pressure and Vacuum for IS Machines.” The talk highlighted how selecting the right vacuum systems and compressors directly impacts and improves efficiency, sustainability, and energy savings in glass container manufacturing.

With its strategic location bridging Europe, Middle East, Africa and Asia, Istanbul served as the perfect hub for meeting global glass industry professionals. Pneumofore is expanding its footprint in these regions as demand grows for energy-efficient pneumatic solutions. With numerous installations already operating under extreme ambient conditions, Pneumofore’s air-cooled Rotary Vane systems set the benchmark for glassmakers seeking reliable, trouble-free machines. Engineered for long-term efficiency with low energy consumption and reduced CO₂ emissions, Pneumofore’s vacuum pumps and compressors deliver the lowest Total Cost of Ownership for high-demand industrial environments such as the glass industry.

Pneumofore, a global leader in Rotary Vane vacuum pumps and compressed air technology, has expanded its vacuum system installation at Kioo, one of the largest container glass manufacturers in East Africa. This milestone follows nearly a decade of successful operation and strong customer satisfaction with Pneumofore’s energy-efficient vacuum solutions for the glass industry.

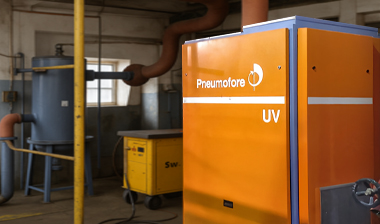

The partnership began in 2016 with the installation of Pneumofore UV16 Rotary Vane vacuum pumps to support the moulding process of IS machines. Since then, the customer has relied on the proven reliability and efficiency of Pneumofore technology. Kioo Glass progressively expanded its system with additional UV16 vacuum units in 2017, 2018, and 2020, bringing the total to five vacuum pumps operating continuously with high performance and minimal downtime.

At Glasstec 2024, Kioo Glass engineers visited the Pneumofore booth to share their positive feedback and confirm their new plans for plant expansion. Based on their experience of the proven reliability and efficiency of Pneumofore’s technology, Kioo Glass finalized an order for six additional UV16 pumps, boosting the total vacuum capacity to over 10,000 m³/h at their Dar es Salaam facility.

Located on the East African coast, Tanzania is a country with high ambient temperatures frequently exceeding 30°C. This climate poses specific operational challenges. Kioo Glass required equipment capable of withstanding hot climate conditions. To meet these demands, Pneumofore will deliver the new units in the HC (Hot Climate) air-cooled configuration, ideal for tropical environments. All vacuum pumps will also feature Variable Speed (VS) drives for optimized energy efficiency and adaptability to the dynamic demands of container glass production.

Kioo Glass operates its vacuum system independently, thanks to hands-on training provided by Pneumofore during initial commissioning of the first installed vacuum pumps. The total OEM-independence, low maintenance needs and robust design of the UV16 Rotary Vane vacuum pumps were key factors in choosing Pneumofore technology again to expand the installation.

Known for their low rotation speed, active sealing system, and low operating temperature, the UV series vacuum pumps offer unmatched energy efficiency and reliability over decades. When serviced regularly with genuine Pneumofore spare parts, these vacuum systems are covered by a 10-year energy efficiency warranty, demonstrating long-term performance.

This latest expansion reinforces Pneumofore’s dedication to sustainable, long-term performance vacuum solutions in demanding industrial environments. By supporting customers like Kioo Glass with reliable and energy-efficient equipment, Pneumofore contributes to lowering CO₂ emissions, reducing operating costs, and offer the lowest Life Cycle Cost for industrial vacuum systems.

Pneumofore is proud to support the greener future of sustainable marine technology with the supply of its innovative Rotary Vane gas compressors for the latest generation of LNG-powered ships. Italian shipbuilding leader Fincantieri is delivering two revolutionaries Sphere-class cruise ships to Princess Cruises, part of Carnival Corporation. These vessels are powered by Liquefied Natural Gas (LNG) and represent a major step forward not only in luxury cruising but also in reducing CO2 emissions and enhancing sustainability in the marine industry.

The first vessel in the Sphere class entered service in 2024. It is the largest ship built for Princess Cruises and the company’s first ship using liquefied natural gas propulsion. The second vessel is scheduled for delivery in 2025. These impressive cruise ships, with a tonnage of 175.500 and capacity for 4.300 guests, will be among the largest LNG-powered cruise ships ever built in Italy and they exemplify the future of eco-friendly cruising.

Pneumofore successfully presented its industry-leading vacuum and compressed air solutions at CanTech The Grand Tour 2025, held in Brussels, Belgium. With decades of expertise in the aluminum canmaking industry, the company presented its Rotary Vane technology, world-renowned for the high energy efficiency, low maintenance needs, and the lowest Life Cycle Cost available in the market.

Pneumofore was also invited among the keynote speakers at the concurrent technical conference, during which the company’s President, Eng. Daniel Hilfiker, hold the presentation titled “Energy Balance and CO2.” His session addressed the global sustainability challenges in can production and explored how reducing CO2 emissions and optimizing energy consumption through the use of energy-efficient pneumatic equipment can lead to long-term cost savings. Attendees gained valuable insights into making smarter investments in industrial machinery by considering energy consumption and the overall Total Cost of Ownership.

Pneumofore’s participation reinforced its commitment to sustainable canmaking by delivering high-efficient vacuum pumps and compressors designed for durability, constant performance over decades, and minimal environmental impact.

Weck Glaswerk, one of the most historical and renowned glassworks in Germany, is relying since decades on the Rotary Vane technology for the supply of vacuum and compressed air at the IS machines.

In 2017, for the expansion of its production plant in Bonn, the company installed the first Pneumofore UV30 vacuum pump.

This Rotary Vane machine fully met the expectations. The efficient non-stop operation and the ability to independently service the machine reinforced Weck’s faith in Pneumofore.

In fact, the company installed a second Pneumofore UV30 unit, equipped with Variable Speed drive, and commissioned a Pneumofore A400.4 low pressure air compressor for the supply of 3 bar(g).

Owing to the steady running of the Pneumofore machines under full load over the years, Weck Glaswerk was happy to document the results and the confirmed power consumption savings with a video testimonial. With a pure and honest testimonial, Weck is demonstrating the improvements achieved in meeting the demanding German carbon footprint reduction rules.

From a Swiss engineering company founded in Italy in 1923 to a worldwide leader in Rotary Vane vacuum pumps and compressed air solutions for industrial applications worldwide, Pneumofore has continuously expanded its presence across the globe setting the benchmark for durability, constant efficiency and the lowest Life Cycle Cost in the market. A journey started in Turin over 100 years ago and further increased in the last decades. Nowadays, Pneumofore compressors and vacuum pumps operate in over 70 countries across five continents, even in remote locations, in altitude and on offshore platforms. Customers choose Pneumofore’s Rotary Vane pneumatic machines for their exceptional durability, ease of maintenance and high energy savings. Committed to sustainability and CO2 reduction, we continue to shape the future of industrial vacuum and compressed air technology since 1923.