Two-Decade-Long Success Story in Dresden, Germany

As a trusted supplier of cutting-edge vacuum and compressed air solutions for the hollow glass industry and leveraging on its strong presence in Asia, Pneumofore attended the 33rd China Glass Expo, held in Shanghai from April 25 to 28. This annual event is dedicated on the entire industrial chain of glassmaking within the Chinese glass market, offering a great platform for showcasing innovative technologies and enhancing new business collaborations.

With its constant focus on enhancing efficiency and sustainability, Pneumofore’s solutions garnered significant attention among the industry professionals attending the event. With the collaboration of its local partner, Ninesun, Pneumofore confirms its dedication to providing localized support and solutions to meet the unique needs of the glass manufacturing sector across China.

Pneumofore featured among the keynote speakers at Latamcan, the technical conference and exhibition for canmakers and suppliers operating in Central and South America and one of the most important meeting points for the metal packaging sector.

After the recurring successes in Brazil and Mexico, in 2024 the event stopped for the first time in Buenos Aires, Argentina, with a record-breaking number of attendees, canmakers and suppliers operating within the LATAM can industry.

Leveraging on the company’s 100 years of expertise, Mr. Rolf Hilfiker, CEO of Pneumofore, held a technical speech focused on compressor efficiency in 2-pc can production. Mr. Hilfiker highlighted the available strategies and customized solutions for minimizing energy waste and achieving maximum cost savings and higher sustainability.

Pneumofore’s participation at the event underscored the company’s focus on the Latin American market, where its presence is constantly expanding and it is supported by a committed local distributor network, like 7Ogun who attended the event. With a strong focus on innovation and sustainability, Pneumofore continues to drive efficiency and excellence, strengthening its position as a preferred partner for the global metal packaging industry

Pneumofore showcased its commitment to pioneering sustainable vacuum and compressed air solutions for can production at CanTech The Grand Tour, held this year in Mumbai, India. At each edition, this leading conference and tabletop exhibition gathers together key decision makers, technical experts and global suppliers, maximizing the networking opportunities and providing attendees with access to the latest and most efficient production technologies.

Eng. Daniel Hilfiker, President of Pneumofore, featured among the keynote speakers during the technical conference with a presentation that highlighted the company’s vision for sustainable can production. With a strong focus on environmental responsibility and energy efficiency, the presentation gave an in-depth overview of Pneumofore’s pioneering Rotary Vane technology and the strategies aimed at minimizing the Total Cost of Ownership and

environmental impact of pneumatic equipment in canmaking. Leveraging on 100 years of technical expertise, Pneumofore reaffirmed its unwavering commitment to driving positive change in the can industry.

Hannover Messe 2023, the world’s premier trade show for the global industry and technical innovations, offered a perfect opportunity to begin the celebrations of Pneumofore 100 Year Anniversary: a goal that no other company in the vacuum and compressed air market can match.

Within the ComVac show, the fair’s main hub for vacuum and compressed air technologies, Pneumofore Rotary Vane solutions and new technical developments had central stage, demonstrating how the company’s centenary experience is a moving force toward constant evolution and reliable solutions for the industry’s most important challenges, including climate protection, energy-saving solutions and sustainability goals.

The company was present with a newly designed booth and, for the first time, it displayed the K2.60 Gas Booster Compressor.

Spotlights were also on the state-of-the-art UV Series Rotary Vane vacuum pumps, represented by the UV24 VS37 unit with Variable Speed drive for the optimal coverage of the vacuum needs with the lowest electrical power consumption.

Pneumofore Rotary Vane units’ constant performance and low Life Cycle Cost are proved on a daily basis and running trouble-free since decades in many industries worldwide, even in harsh or hot climate conditions. With constant focus on innovation and energy saving solutions, Pneumofore is inspiring the future since 1923.

The A400 air compressors shown in the picture have been running continuously for three years. Operating in harsh conditions, with ambient temperatures ranging from -10 °C in winter to +40 °C during the summer, these air-cooled machines were merely paused for maintenance purposes. The initial 23.000 hours of operation represent only the end of the break-in for these compressors. Their Rotary Vane Air-End, which is the core of Pneumofore technology, is built to last and run smoothly with top efficiency for decades. The units’ reliability is the foundation to achieve extraordinary results, but it is not sufficient alone: required is a proper state-of-art installation which is simplified by following the system engineering support included in every Pneumofore solution. We are proud to have surpassed the customer’s expectations and look forward to additional orders for installations in rough climate conditions.

Industry advancements and innovations in the glass industry took center stage at Glasstec 2018, the world’s leading tradeshow for equipment and services for glass production. The event, that celebrated its 25th anniversary, welcomed in four days about 42,000 visitors from all over the world, with an increased attendance trend compared to the previous edition. As a leading supplier of centralized vacuum and compressed air systems and a traditional exhibitor at Glasstec, Pneumofore presented itself with a new booth concept, designed to highlight the benefits of the company’s Rotary Vane technology and tailored solutions for the glass industry. Spotlights were on the UV50 vacuum pump – here presented in its Variable Speed version – which raised great interest from visitors. This unit is one of the most popular vacuum pump in worldwide glassworks, appreciated for its constant performance over time and high energy savings on the long-run. The response from the fair has been consistently positive, with high-level conversations with both new and consolidated customers, which make us looking very positively into 2019.

Gastech, one of the world’s most important conference and exhibition for the gas, LNG end energy industries, welcomes for the first time Pneumofore vacuum and compressed air and gas solutions. The company will present its latest innovations for the global energy sector which include transportable air-cooled vacuum systems for pipeline drying, compressors for gas processing and gas treatment, and vacuum systems for vapour recovery processes. Spotlights will be on the double-stage UV Series vacuum pumps with water vapour suction capability. Visitors will touch first hand a UV16 H model with roots pump, which will be presented at the tradeshow in its Variable Speed and Hot Climate version. Specially designed for pipeline drying, these vacuum pumps operate in a single-stage configuration during the initial phase, down to a pressure level of approximately 50 mbar(a). The second-stage roots pump is then activated in order to improve the ultimate vacuum level down to roughly 0,03 mbar(a) until the final dew point. The two pump stages are ready-to-use, as they require only a power supply and single pipe connection for operation. They are assembled into a heavy-duty frame that can easily fit mobile operations on trucks, containers or vessels, both off- or on-shore. These vacuum pumps have a proven track record of achieving excellent and fast pipeline dryness compared to other drying methods. Gastech will be held from 17 to 20 September 2018 in Barcelona, Spain. Pneumofore welcomes you at Booth C106.

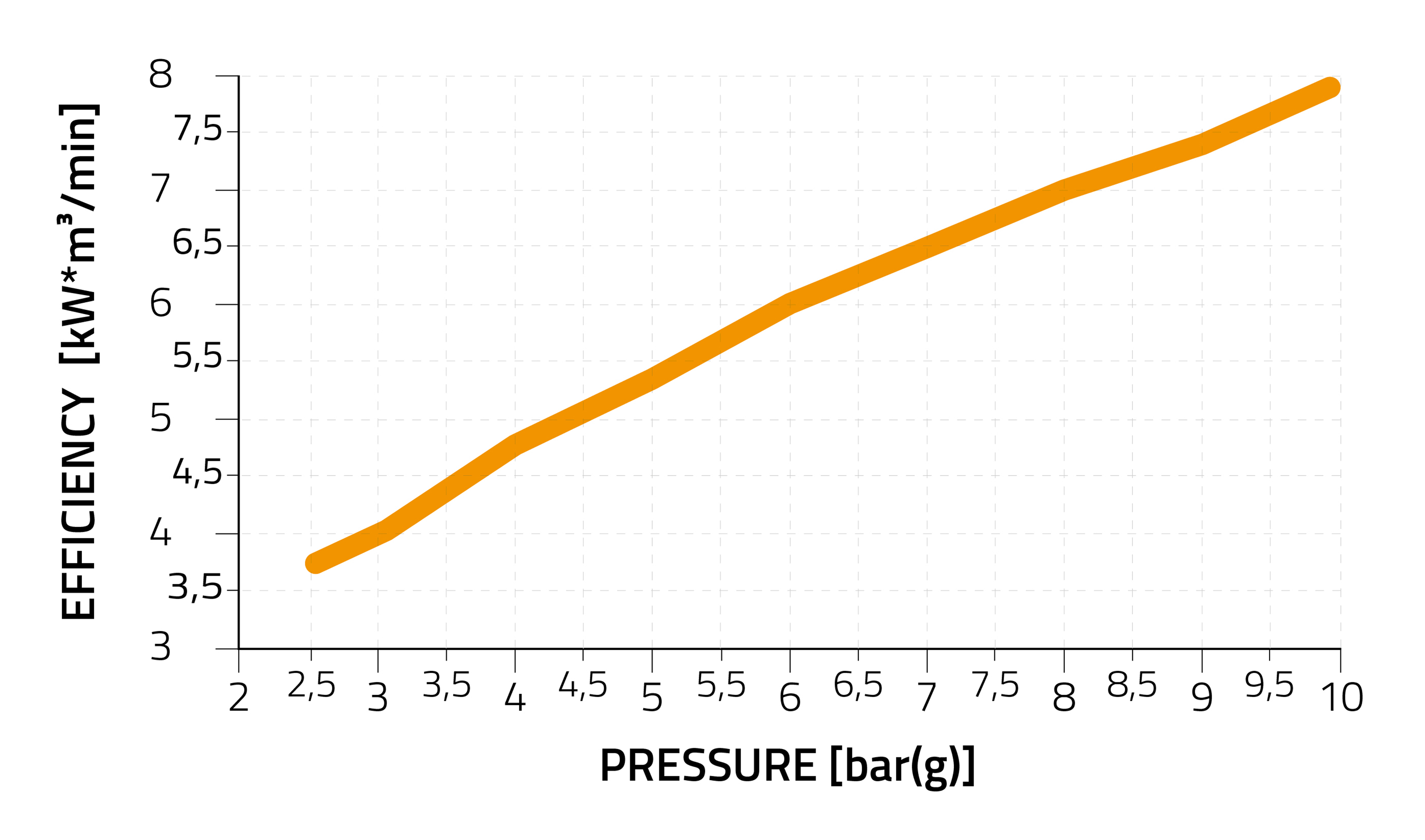

It is common practice to compress the air up to 8 bar(g) or more, even when the required pressure is much lower, for instance 3.5 bar(g) which is less than half of the initial pressure. In such frequent cases, a considerable amount of energy gets lost. In order to optimize the efficiency, the low pressure compressed air could be generated separately using dedicated low pressure compressors. Indeed, it is more efficient to compress the air at the exact required pressure while pressure reducers are appropriate only for little pressure differences or fractions of one bar. Pneumofore promotes the idea of low pressure loop in compressed air systems for the consistent savings achievable with this solution. The cost for the additional low pressure pipeline is normally paid off within few months. It is part of the Pneumofore offer to calculate the dimensions of the compressed air system at no cost for the customer, in order to guarantee electrical power savings in the long term. Operating from 2,5 to 10 bar(g) with a power range from 10 to 630 kW, the A Series air compressors represent a stable and economical solution for low pressure supply.

- 1

- 2