…are Atex certified and are successfully running in many installations, mainly in Europe and Asia, for the recovery of gasoline or specific vapors. The high technical level and quality of the contacts is motivating the company to further increase its presence in similar international exhibitions and conferences in 2018….

…aims to inspire a new approach toward environmental issues and a deeper understanding of the impact of daily habits. The inter-disciplinary path of the project ranges from the history of liquid containers to the analysis of aluminium characteristics, through art, visual communication, photography and design with the intention of discovering…

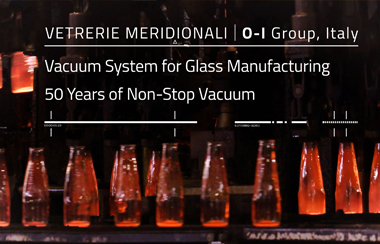

…the glass moulding process, it improves the container glass quality and it increases the production speed of the IS machines. After 50 years of constant efficiency and non-stop vacuum, the company renewed its collaboration with Pneumofore with a new centralized, air-cooled vacuum system designed for higher efficiency and unmatchable energy…

…IS supplier and top quality of raw material is not sufficient. High moulding speed, minimal rejection rate and optimized glass container weight are common targets. With the worlds largest single-stage rotary compressors and pumps up to 300 HP and down to 1 mbar(a), Pneumofore covers all pneumatic requirements of glassworks….

…the local distributor, another relevant result appeared immediately. The hollow glass containers with weight of 450 g were measured again: their weight was reduced to 405 g. Like this, the higher amount of glass required by the increased moulding speed of the IS machines was ‘compensated’ by the minor glass…

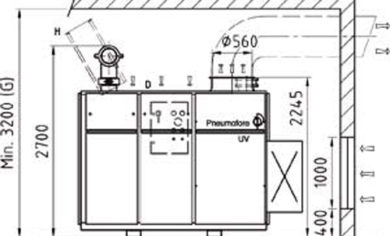

…the compressed air required during the moulding process of hollow glass containers. Pneumofore equipment is frequently seen in hollow glass factories worldwide. In most cases large size vacuum pumps of the UV Series are installed, since our compressors do not always satisfy the huge capacity requirements of compressed air at…

…model UV16 pumps with all dedicated accessories operate continuously since then. The objective of high-speed container glass manufacturing with the lowest available rejection rate was achieved. In October of the same year, the installation of a second UV pump system followed for the Malaya Vietnam Glass Plant. No Service Center…

…in a relatively small area. Pneumofore has supplied over 40 vacuum pumps operating at Saint Gobain plants worldwide for the moulding of glass containers and for the production of tiles and bricks. Some units have been in operation for more than 25 years. The water-cooled models V70 and V100 are…

…the technical team and the importance given to the vacuum system, which strongly contributes to determine the quality and production speed of the glass containers. Piping and accessories are installed according to Pneumofore instructions, the UV units are kept clean and serviced regularly. This professional approach of MGM results from…

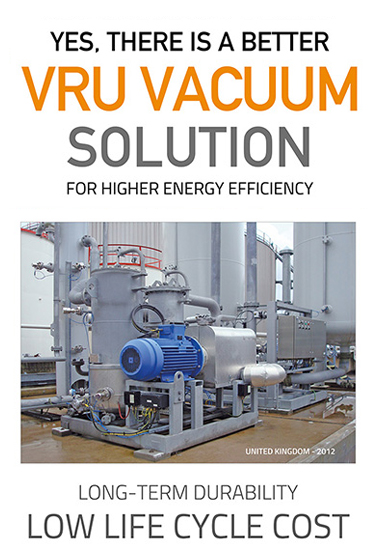

…is a “secondary energy”, just a facility. But the repeated unsuccess motivates to contact colleagues, who faced similar circumstances. Some engineers will never admit their incompetence, others will hunt a long term solution. Target is to have always sufficient vacuum-capacity and -level in the production, better if air cooled and…